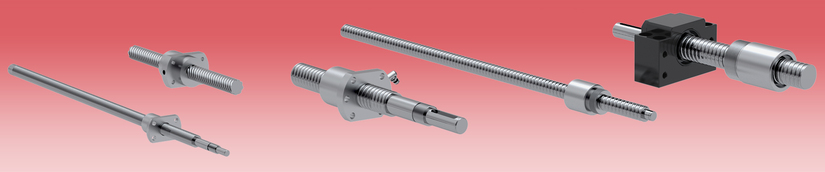

BALL SCREWS

A ball screw converts rotary motion into linear motion. Ball screws are used when a rigid and precise linear driving with high efficiency and intensity is required. The rigidity in combination with the high lead accuracy gives the ball screw drive a precision of 1/10 to a 1/1000 of a millimetre depending on selected play or preload. Due to rolling friction between screw shaft and ball nut, the practical efficiency of a ball screw is between 80 – 90%. This saves energy and motor size. It also allows high intensity as the power losses (waste heat) is 5 to 10 times lower compared to trapezoidal screws.

Depending on required force, speed and durability, different diameters and leads can be selected. A correct selected and maintained ball screw have a very long and predictable service life. Compared to many other linear drive mechanisms, there is practically no gradual loss of performance or precision during the service life.

The Rollco product range is based on rolled ball screws. Rolled ball screws offer the best price-performance for automation, handling and light machine tool needs.

In our workshop in Helsingborg, we customise ball screws according to our customers’ requests. The ball screws are available in standard sizes from 6 mm to 63 mm. Among the accessories, there are different types of support units, housings and nuts with flanges.

In cooperation with CeramicSpeed we offer coating solutions. The long-life coatings provide extremely high corrosion resistance and wear and friction-suppressant properties. Contact us for further information.

READ MORE ABOUT BALL SCREWS ON OUR BLOG ![]()

FURTHER INFORMATION

- Products

- CAD files

- Technical information (pdf)

- Order codes (pdf)

- Support units & recommended screw-shaft diameters (pdf)

- Rollco & CeramicSpeed

- Standard tolerances

CHARACTERISTICS

- High rigidity

- High efficiency

- Optimal price-performance ratio

- Sizes from Ø6 mm to Ø63 mm.

- Additional types on request.

APPLICATIONS

- Machine industry

- Machine tools

- Automated storage and retrieval systems

- Semiconductor industry

- Medical industry